Product Description

No more ring failures! Now Risk-Free press cycles!

During the process of a press cycle, there is a possibility of ring fractures. This can happen due to various reasons. This is an unfortunate and costly experience. The technician needs to spend precious time to remake this case and the additional cost of material adds to the overall cost of such a redo.

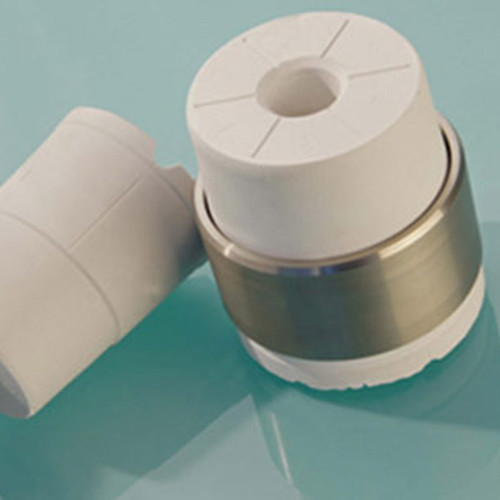

The AP safety belt is a device that prevents this event from happening. The metal ring prevents micro cracks from expanding in the investment material. The geometry of the ring is a 2.5-degree cone, which enables the genius safety belt to slide over the outside of the investment ring. When the ring is in place, it results in the solid protection of the press ring.

The investment and the metal safety belt will be placed separately in the burn out furnace. Before placing the ring in the press furnace, the ingots and the press plunger will be placed first, followed by sliding the safety belt over the ring. It is not necessary to pre-heat the metal ring!

There are two sizes available. One for the AP 200 and one for the AP 300 ring.

After removing the ring from the press oven, it is safe to place it in the general casting area. The metal ring will shed slightly during the cooling phase outside the oven.

To remove the ring from the object, use a clamp, turn the object upside down and gently tap it on a stone or heat resistant surface.