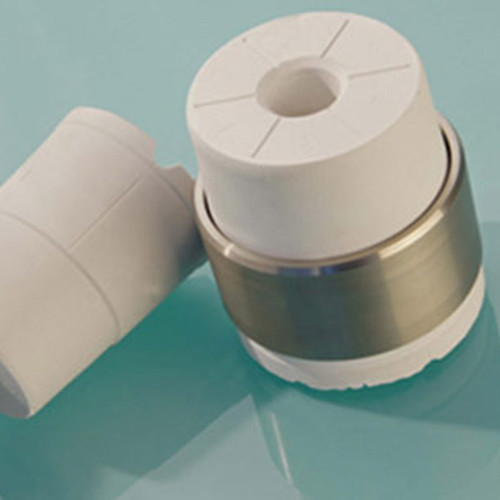

Product Description

The AP 200 and 300 are the only investment rings on the market with a number system on the inside. The numbers show the exact position of the crowns after the press cycle and enables a quick de-vesting process. The lines show precisely, where to cut the ring in order to break off the excess investment parts. The numbers can be found on the bottom of the molds as well as the inside of the silicon ring and on the inside of the lid. The ring can only be closed (or put together) in a precise position due to the individual locks. The piston of the AP 200 is built higher than conventional rings, which allows pressing 3, 2g ingots.

The increased height of the AP 300 allows a larger amount of porcelain to be pressed. It is possible to press up to 6, 2.5g ingots. Depending on the press furnace, it might be necessary to shorten the press plunger using the same amount of ingots. It is also important not to fill the ring above the second line as indicated on the photo. The height of the of ring including ingots and press plunger should not exceed 7.5 cm or 2.95 inches.

With the AP 200 it is possible to press up to 6 anteriors or up to 4 posteriors. The AP 300 can be used to press up to 10 units.

Height of the press plunger:

Using press furnaces from Ivoclar, it is recommended to shorten the press plunger when using multiple ingots. The rule is to cut the plunger when using more than 1 ingot.

AP 200

When using more than 1 ingot, shorten the plunger by the amount of the additional ingots, e.g., using two ingots, shorten the plunger by the height of one ingot. Using 3 ingots, shorten the plunger by the height of 2 ingots, and so on.

AP 300

When using more than 2 ingots, shorten the plunger by the amount of the additional ingots, e.g., using 3 ingots = shorten the height by 1. When using 4 ingots, shorten the height by 2, and so on.

Oven specific:

When working with the Ivoclar EP 3000 and 5000, as well as the Dekema Press-i-Dent, only fill the AP 300 ring to the second line indicated on the inside of the silicon ring. This specific oven has a plunger, which pushes through the opening of the ring to push down the ingots.

For the Zubler Vario 300 and the Dekema Press-i-Dent do not shorten the plunger, since the plunger will press until it reaches the upper level of the investment ring.